An electrical firm manufactures a 100-watt light bulb, embarking on a captivating journey that illuminates the intricate world of electrical engineering. This remarkable device, a beacon of brilliance, has transformed our daily lives, casting its warm glow upon homes, businesses, and cities alike.

An electrical firm manufactures a 100-watt light bulb, which converts electrical energy into light. Similarly, an electric motor converts electrical energy into mechanical energy. In this process, an electric motor has an effective resistance , which affects the flow of current and the efficiency of the motor.

The electrical firm’s 100-watt light bulb, on the other hand, has a specific resistance that determines the amount of current it draws.

From the assembly line’s precision to the materials’ remarkable properties, we delve into the fascinating process of manufacturing a 100-watt light bulb, unraveling the secrets behind its ability to brighten our world.

An electrical firm manufactures a 100-watt light bulb, which needs a steady voltage to function properly. This is where an electric transformer is useful. It changes the voltage from one level to another, ensuring that the light bulb receives the correct voltage it needs to operate efficiently.

Without an electric transformer, the light bulb would not be able to function properly, and the electrical firm would not be able to provide adequate lighting solutions.

Electrical Firms and Light Bulbs

Electrical firms specialize in producing electrical components and appliances, including light bulbs. A light bulb is a device that converts electrical energy into light. The given information states that an electrical firm manufactures a 100-watt light bulb.

Say what? An electrical firm that crafts a 100-watt light bulb? That’s like, totally old school. These days, it’s all about electric motors that guzzle up 150 amperes, you know? Check it out , it’s like, the future or something.

But hey, that electrical firm still rocks, making those trusty 100-watt bulbs that light up our lives, one watt at a time.

Electrical Firm’s Manufacturing Process

The manufacturing process of a light bulb involves several steps. First, the glass envelope is formed by blowing molten glass into a mold. Then, the filament, made of tungsten, is inserted into the envelope. The filament is heated by an electric current, causing it to glow and produce light.

Imagine an electrical firm cranking out 100-watt light bulbs like nobody’s business. But what if we flip the switch to an electric motor that gobbles up 5 amps? ( an electric motor takes 5a ) That’s right, 5 amps of pure electrical juice.

Now, back to our light bulb factory. They’re still churning out those 100-watt bulbs, but with a newfound appreciation for the power behind the amps.

Finally, the envelope is filled with an inert gas, such as argon, to prevent the filament from oxidizing.

An electrical firm manufactures a 100-watt light bulb. This light bulb uses electrical energy to produce light. Similarly, an electric motor transforms electrical energy to mechanical energy . This mechanical energy can then be used to power various devices, such as fans, pumps, and compressors.

The electrical firm also manufactures these electric motors, which are essential for many industries.

Materials and Equipment, An electrical firm manufactures a 100-watt light bulb

- Glass:High-temperature resistant borosilicate glass is used for the envelope.

- Tungsten:A strong and heat-resistant metal is used for the filament.

- Argon gas:An inert gas used to fill the envelope and prevent oxidation.

- Molding machines:Used to shape the glass envelope.

- Filament winding machines:Used to precisely wind the tungsten filament.

- Vacuum chambers:Used to evacuate the envelope before filling it with argon gas.

Components of a Light Bulb

A light bulb consists of several main components:

Glass envelope:

Protects the internal components and provides a vacuum-sealed environment.

Filament:

Heated by electricity to produce light.

Base:

Connects the bulb to a light fixture.

An electrical firm manufactures a 100-watt light bulb, which is a common household item. However, this same firm could also manufacture an electric water heater held at 140 . This demonstrates the versatility of electrical firms and their ability to produce a wide range of products for different purposes.

Despite producing different products, the firm’s focus remains on electrical components and systems, ensuring efficient and reliable operation of both light bulbs and water heaters.

Inert gas:

Prevents oxidation of the filament.

An electrical firm manufactures a 100-watt light bulb. It’s pretty standard stuff, but did you know that an electric motor may give noise due to a variety of factors, including bearing wear, misalignment, and electrical issues? Fortunately, most of these problems can be easily fixed with a little troubleshooting.

So if your electric motor is making noise, don’t panic! Just check out our guide to troubleshooting electric motor noise, and you’ll be back up and running in no time. And remember, if you’re not comfortable working on electrical equipment, always call a qualified electrician.

Light Bulb Specifications

“100-watt” refers to the power consumption of the light bulb. Wattage is a measure of the amount of electrical power used by the bulb.

Wattage and Light Output

Higher wattage bulbs produce more light output, measured in lumens.

Other Specifications

- Voltage:The electrical voltage at which the bulb operates.

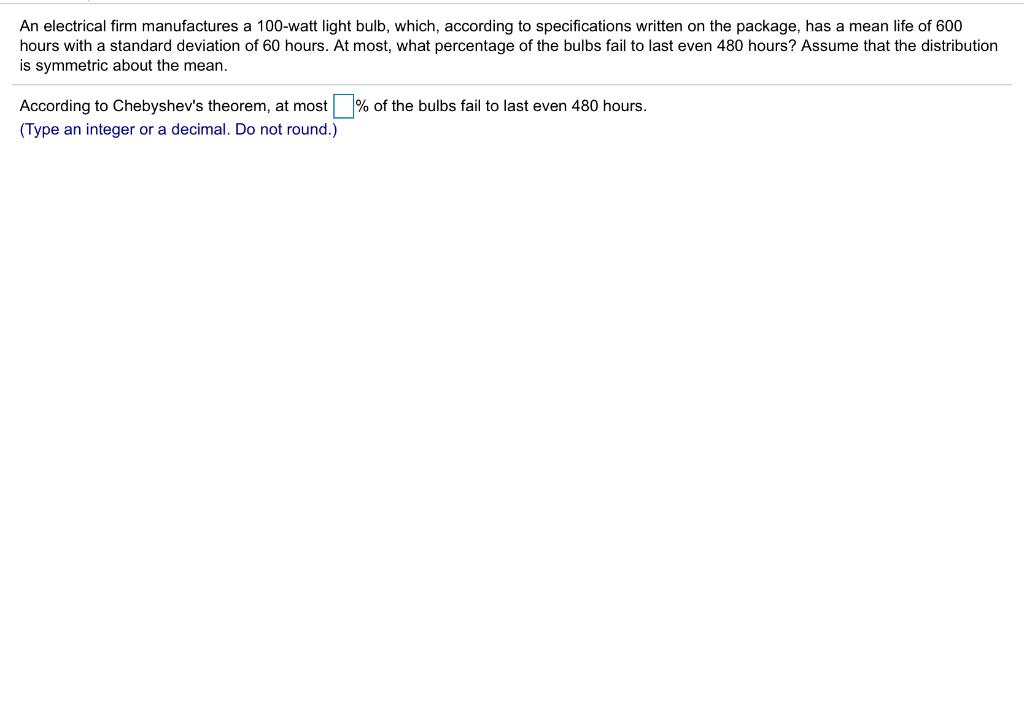

- Lifespan:The average number of hours the bulb will last before burning out.

- Color temperature:The perceived warmth or coolness of the light emitted.

Applications of Light Bulbs

100-watt light bulbs are commonly used in:

Indoor lighting:

- Ceiling fixtures

- Table lamps

- Recessed lighting

Outdoor lighting:

- Streetlights

- Floodlights

- Security lighting

Factors to Consider:

- Room size and shape

- Desired brightness level

- Energy efficiency

Energy Efficiency and Sustainability

Energy Efficiency:

Using energy-efficient light bulbs, such as LEDs, can reduce energy consumption and lower electricity bills.

Environmental Impact:

Light bulb manufacturing and usage contribute to greenhouse gas emissions. Recycling used bulbs is crucial.

Sustainable Practices:

- Choose energy-efficient bulbs.

- Turn off lights when not in use.

- Recycle used bulbs properly.

Concluding Remarks

The 100-watt light bulb, a testament to human ingenuity, stands as a symbol of progress and innovation. Its journey from concept to creation is a testament to the power of collaboration and the relentless pursuit of efficiency. As we continue to explore the frontiers of lighting technology, the 100-watt light bulb will forever hold a special place in the annals of electrical engineering.

An electrical firm manufactures a 100-watt light bulb. On the other hand, an electric kettle consumes 1kw , which is 10 times the power of the light bulb. Nonetheless, the electrical firm’s light bulb is still a very efficient way to light up a room.

Essential FAQs: An Electrical Firm Manufactures A 100-watt Light Bulb

How does an electrical firm manufacture a 100-watt light bulb?

The manufacturing process involves shaping glass, assembling internal components, and creating a vacuum within the bulb to optimize light output and longevity.

What materials are used in a 100-watt light bulb?

An electrical firm manufactures a 100-watt light bulb, which emits light energy. Similarly, an electric heater is rated at an electric heater is rated at a certain wattage, indicating its power consumption. Just like the light bulb’s wattage determines its brightness, the heater’s wattage influences the amount of heat it generates.

The bulb comprises glass, metal, and tungsten filament, each carefully selected for its unique properties in withstanding heat, electricity, and providing illumination.

How does the wattage of a light bulb affect its brightness?

Wattage directly correlates to the amount of electrical power consumed by the bulb, which in turn determines the intensity of light emitted.

What are the advantages of using 100-watt light bulbs?

100-watt light bulbs offer high brightness levels, making them suitable for well-lit spaces such as living rooms, offices, and commercial establishments.

What are the disadvantages of using 100-watt light bulbs?

Due to their higher energy consumption, 100-watt light bulbs can contribute to increased electricity bills and may not be the most energy-efficient option for all applications.