A manufacturer uses electrical fuses in an electronic system – When it comes to safeguarding delicate electronic systems from electrical hazards, manufacturers rely on a trusty sidekick: electrical fuses. These unsung heroes play a crucial role in preventing catastrophic failures and ensuring the smooth operation of our gadgets.

A manufacturer uses electrical fuses in an electronic system to prevent damage from electrical overloads. However, if you’re looking for ways to charge an object with static electricity, you can read this article for three simple methods. Returning to the topic, the electrical fuses are designed to melt and break the circuit when the current exceeds a safe level, protecting the electronic components.

Electrical fuses are like vigilant guardians, standing ready to sacrifice themselves to protect the sensitive components within electronic devices. By understanding their purpose, selection criteria, and maintenance needs, we can appreciate the vital role they play in keeping our electronics humming along.

Yo, a manufacturer uses electrical fuses in an electronic system to protect against overloads. But hold up, owning an electric vehicle ain’t all sunshine and rainbows. Check out this link to 10 hidden costs of owning an electric vehicle that’ll make you rethink your ride.

And remember, electrical fuses still got your electronic system’s back.

Electrical Fuse Fundamentals

Electrical fuses are crucial components in electronic systems, safeguarding them from overcurrent and short circuits. Understanding their purpose and working principle is essential for effective system design and maintenance.

To ensure the safe operation of an electronic system, manufacturers employ electrical fuses to protect against electrical overloads. These devices interrupt the flow of electricity when it exceeds a predetermined level, safeguarding the system from damage. Interestingly, a battery, a prime example of producing electricity using chemical reactions , also plays a crucial role in providing power to various electronic devices.

By integrating electrical fuses with batteries, manufacturers can ensure both safety and functionality in their electronic systems.

Fuses operate by interrupting the current flow when it exceeds a predetermined level, thereby protecting downstream components from damage. They are made of a thin wire or strip that melts and breaks the circuit when the current becomes too high.

A manufacturer uses electrical fuses in an electronic system to protect against overloads and short circuits. These devices are designed to interrupt and de-energize an electrical circuit by breaking the current flow when the current exceeds a safe level. This helps prevent damage to the electronic system and can also prevent fires.

Electrical fuses are an important safety feature in many electronic devices and appliances.

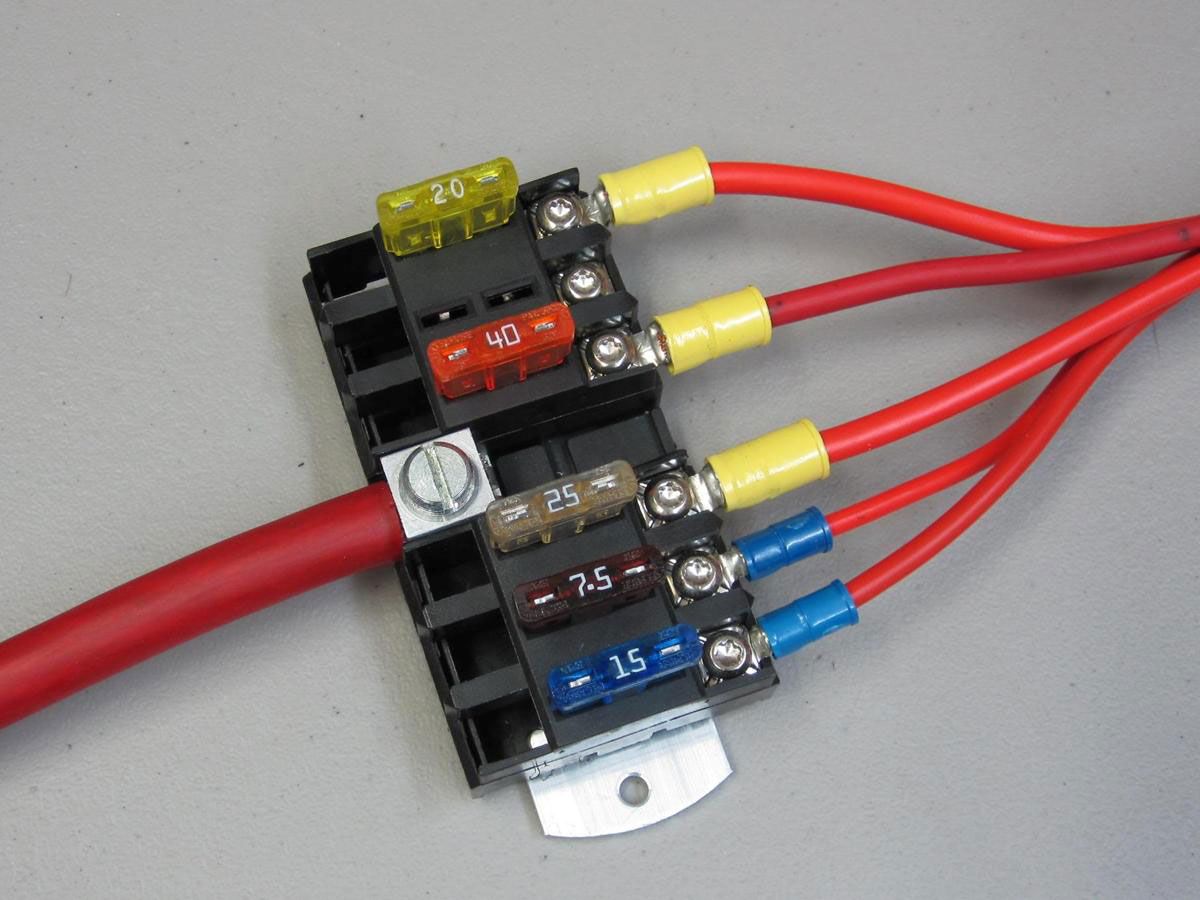

Types of Fuses, A manufacturer uses electrical fuses in an electronic system

- Disposable Fuses:Designed for one-time use, these fuses blow and must be replaced when the current exceeds their rating.

- Resettable Fuses:Can be reused after the fault condition is cleared. They contain a bimetallic strip that bends and breaks the circuit when overheated.

- High-Voltage Fuses:Used in high-voltage applications, these fuses employ special extinguishing media to quench the arc produced when they blow.

- Current-Limiting Fuses:Limit the fault current to a safe level, preventing damage to downstream components.

Fuse Selection and Placement: A Manufacturer Uses Electrical Fuses In An Electronic System

Selecting the right fuse for an electronic system is crucial to ensure proper protection. Factors to consider include:

- Current Rating:The fuse should have a current rating slightly higher than the normal operating current of the circuit.

- Voltage Rating:The fuse should be rated for the maximum voltage present in the circuit.

- Type:Choose the appropriate fuse type based on the application and desired protection characteristics.

Proper fuse placement is also important:

- Accessible:Fuses should be easily accessible for inspection and replacement.

- Away from Heat Sources:Avoid placing fuses near heat sources that could affect their operation.

- Correct Mounting:Fuses should be securely mounted to prevent vibration or loose connections.

Fuse Operation and Protection

Fuses operate under normal and fault conditions:

- Normal Operation:When the current is within the fuse’s rating, it remains intact, allowing current to flow.

- Fault Condition:When the current exceeds the fuse’s rating, the fuse element melts, breaking the circuit and interrupting the current flow.

Fuses play a vital role in protecting electronic components by:

- Limiting Overcurrent:Fuses prevent excessive current from flowing through the circuit, protecting components from damage.

- Interrupting Short Circuits:In case of a short circuit, fuses quickly break the circuit, preventing the flow of high fault currents.

Fuse Monitoring and Maintenance

Monitoring fuse status is essential for system reliability:

- Visual Inspection:Fuses can be visually inspected for blown elements.

- Test Equipment:Fuse testers can be used to check fuse continuity and determine if they have blown.

Regular fuse maintenance is crucial:

- Replacement:Blown fuses should be replaced promptly.

- Inspection:Fuses should be inspected regularly for signs of damage or corrosion.

- Cleaning:Fuse holders and contacts should be cleaned to ensure proper connections.

Alternative Overcurrent Protection Methods

While fuses are widely used, alternative overcurrent protection methods exist:

- Circuit Breakers:Resettable devices that automatically interrupt the current flow when it exceeds a set threshold.

- Solid-State Circuit Protectors:Electronic devices that use semiconductor switches to limit or interrupt current.

- Surge Suppressors:Protect circuits from transient voltage spikes.

The choice of protection method depends on factors such as cost, reliability, and application requirements.

Yo, check it! A manufacturer uses electrical fuses in an electronic system to protect the circuitry from electrical overloads. These fuses provide an uninterrupted electrical path for current flow , allowing electricity to pass through without any issues. But if there’s a surge in current, the fuse blows, breaking the circuit and preventing damage to the system.

It’s like a superhero for your electronics!

Last Point

In the realm of electronics, electrical fuses stand as indispensable protectors, safeguarding our devices from the perils of electrical overloads and short circuits. Their simple yet effective design has made them a cornerstone of electronic safety, ensuring that our gadgets remain reliable companions in our daily lives.

Answers to Common Questions

Why are electrical fuses important in electronic systems?

Electrical fuses act as safety switches, interrupting the flow of electricity when it exceeds a predetermined level, protecting sensitive electronic components from damage.

How do I choose the right fuse for my electronic system?

When manufacturers use electrical fuses in an electronic system, it’s like putting a charged particle in an electric field – the charged particle experiences a force that can cause it to move. In the same way, the electrical fuse experiences a force that can cause it to blow, protecting the electronic system from damage.

Fuse selection depends on factors like the expected current draw, voltage, and fault conditions. Consulting the manufacturer’s specifications or an electrician is recommended.

How often should I inspect and replace fuses?

Regular inspection and replacement of fuses are crucial for maintaining optimal protection. The frequency depends on the operating environment and usage patterns.

A manufacturer uses electrical fuses in an electronic system to protect it from damage caused by overcurrent. A typical day as an electrical engineer might involve designing, testing, and troubleshooting electrical systems, including those that use fuses. The engineer would need to have a strong understanding of electrical theory and safety practices, as well as the ability to read and interpret electrical schematics.

After a day’s work, the engineer might return to the manufacturer to help design a new electrical system that incorporates fuses.