An electric motor turns a flywheel through a captivating dance of energy conversion, where electricity transforms into motion and rotational force takes center stage. This dynamic duo combines to power a wide range of applications, from stabilizing power grids to propelling hybrid vehicles.

An electric motor turns a flywheel through the power of electricity, which is generated by two electromagnets as explained here . This electromagnetic force creates a spinning motion that turns the flywheel, providing continuous energy.

Dive into the world of electric motors and flywheels, where innovation spins at the speed of electricity.

At the heart of this system lies the electric motor, a maestro of energy conversion. It orchestrates the transformation of electrical energy into mechanical energy, setting the flywheel in motion. The flywheel, in turn, becomes a reservoir of rotational energy, storing the kinetic energy imparted by the motor.

The Purpose of an Electric Motor and Flywheel

An electric motor is a device that converts electrical energy into mechanical energy. It consists of a rotor (the rotating part) and a stator (the stationary part). When an electric current flows through the rotor, it creates a magnetic field that interacts with the magnetic field of the stator, causing the rotor to spin.

An electric motor turns a flywheel through a belt, which in turn drives a generator. The generator produces electricity, which is then used to power an electric heater with the total surface area of 0.25 . The heater warms the air, which is then circulated by a fan.

The flywheel stores energy, which is released when the generator is turned on. This allows the generator to produce electricity even when the motor is not running.

A flywheel is a heavy wheel that stores energy through rotational motion. When the electric motor spins the flywheel, it stores energy in the form of kinetic energy. This energy can then be released by slowing down the flywheel, which in turn drives the electric motor in reverse, generating electricity.

The electric motor, powered by electricity, spins a flywheel through its connected gears. The spinning flywheel’s kinetic energy can be used to power various devices, such as an electric lamp of 100 ohm . The electric motor’s continuous rotation ensures a steady supply of energy to the flywheel, which in turn provides reliable power to the connected devices.

Combining an electric motor and flywheel has several benefits. First, it can improve the efficiency of the system by reducing energy losses. Second, it can provide a backup power source in the event of a power outage. Third, it can reduce the peak demand for electricity, which can save money on energy bills.

An electric motor turns a flywheel through a belt drive, converting electrical energy into kinetic energy. This flywheel can then be used to power other devices, such as a generator or an electric kettle . The electric kettle consumes 1kW of power, which is a relatively high amount of energy.

However, this energy is used to heat water quickly and efficiently, making it a convenient appliance for many households. An electric motor turns a flywheel through a belt drive, converting electrical energy into kinetic energy.

The Process of Converting Electrical Energy to Mechanical Energy

An electric motor converts electrical energy into mechanical energy through the interaction of magnetic fields. When an electric current flows through the rotor, it creates a magnetic field. This magnetic field interacts with the magnetic field of the stator, causing the rotor to spin.

The strength of the magnetic fields and the amount of current flowing through the rotor determine the amount of torque produced by the motor. Torque is a measure of the force that causes the rotor to spin. The higher the torque, the more force the motor can produce.

The speed of the motor is determined by the frequency of the alternating current (AC) flowing through the stator. The higher the frequency, the faster the motor will spin.

The Mechanics of Flywheel Energy Storage

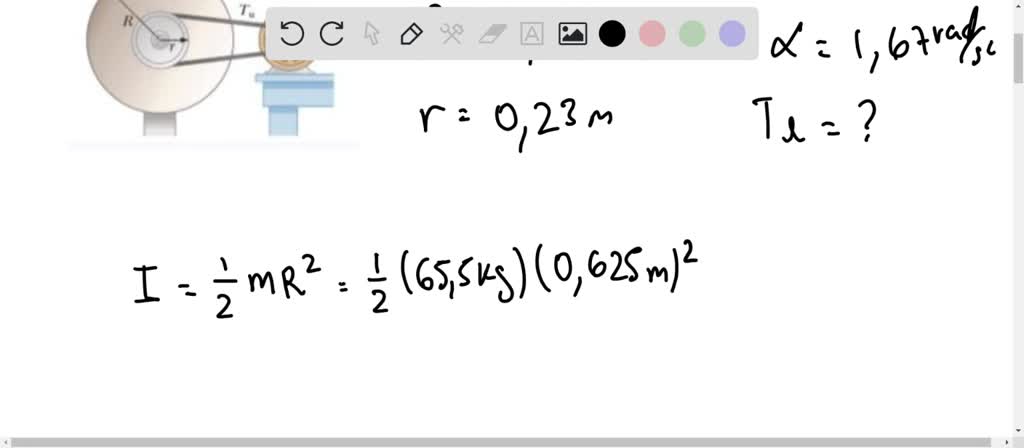

A flywheel stores energy through rotational motion. The amount of energy stored in a flywheel is determined by its mass, its radius, and its angular velocity. The greater the mass, the greater the radius, and the faster the angular velocity, the more energy the flywheel will store.

Flywheels can be made from a variety of materials, including steel, aluminum, and composite materials. The material used will determine the strength, weight, and cost of the flywheel.

An electric motor turns a flywheel through a variety of means, including belts, gears, and direct drive. An electric kitchen utensil is a common example of an electric motor turning a flywheel. The motor drives the flywheel, which in turn powers the utensil.

This type of arrangement is often used in blenders, food processors, and other kitchen appliances.

Flywheels have a number of advantages for energy storage. They are relatively efficient, they can store energy for long periods of time, and they can be discharged quickly.

The Control and Management of the System

The electric motor and flywheel are controlled and managed by a variety of sensors, controllers, and algorithms. These components work together to ensure that the system operates safely and efficiently.

An electric motor turns a flywheel through a belt or chain, which in turn drives other machinery. An electric kitchen range has a total of four burners, two ovens, and a warming drawer. The electric motor in the range powers the fans that circulate the air in the ovens and the burners that heat the food.

The sensors measure the speed, torque, and temperature of the motor and flywheel. This information is then sent to the controllers, which adjust the current flowing through the motor to maintain the desired speed and torque.

An electric motor turns a flywheel through a belt drive, which in turn drives a generator. The generator produces electricity, which is used to power an electric iron. An electric iron draws a current of 5 amperes . The flywheel stores energy, which is released when the motor is turned off.

This allows the generator to continue to produce electricity for a short period of time, even after the motor has been turned off.

The algorithms are used to optimize the performance of the system. For example, the algorithms can be used to minimize energy losses and to maximize the efficiency of the energy conversion process.

Applications and Use Cases: An Electric Motor Turns A Flywheel Through

Electric motors turning flywheels are used in a variety of applications, including:

- Uninterruptible power supplies (UPSs)

- Electric vehicles

- Industrial machinery

- Renewable energy systems

In UPSs, electric motors turning flywheels are used to provide backup power in the event of a power outage. The flywheel stores energy during normal operation, and this energy is released to power the UPS when the power goes out.

As the electric motor diligently turns the flywheel through its relentless rotation, we can draw a parallel to the unwavering performance of an electric heater, rated at a formidable 1500 watts an electric heater is rated 1500w . Just as the heater converts electrical energy into comforting warmth, the motor harnesses electrical power to drive the flywheel’s relentless spin.

In electric vehicles, electric motors turning flywheels are used to store energy during braking. This energy can then be used to power the vehicle during acceleration.

In industrial machinery, electric motors turning flywheels are used to smooth out the flow of power. This can help to improve the efficiency of the machinery and to reduce wear and tear.

In renewable energy systems, electric motors turning flywheels are used to store energy from renewable sources, such as solar and wind power. This energy can then be used to power the grid when the renewable energy sources are not available.

Closure

The marriage of an electric motor and flywheel offers a symphony of benefits. From enhancing power quality to providing backup power, this dynamic duo proves its versatility across industries. As technology continues to evolve, we can expect even more innovative applications of this energy-efficient and reliable system.

Essential Questionnaire

How does an electric motor convert electrical energy into mechanical energy?

An electric motor turns a flywheel through a mechanical transmission system, converting electrical energy into kinetic energy. When operating, an electric motor draws 150 amperes of current, indicating its power consumption. The flywheel stores the kinetic energy and releases it back into the system as needed, ensuring smooth and efficient operation of the electric motor.

An electric motor utilizes the principles of electromagnetism. When an electric current flows through a conductor placed in a magnetic field, a force is generated. This force causes the conductor to rotate, converting electrical energy into mechanical energy.

What factors affect the energy storage capacity of a flywheel?

The energy storage capacity of a flywheel depends on its mass, rotational speed, and material properties. Heavier flywheels with higher rotational speeds and materials with high energy density can store more energy.

What are the advantages of using flywheels for energy storage?

Flywheels offer several advantages, including high efficiency, fast response times, long cycle life, and low maintenance requirements. They are also environmentally friendly, as they do not produce emissions during operation.